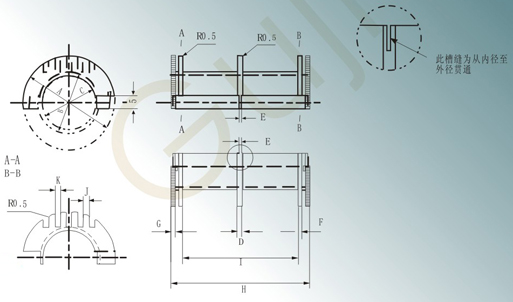

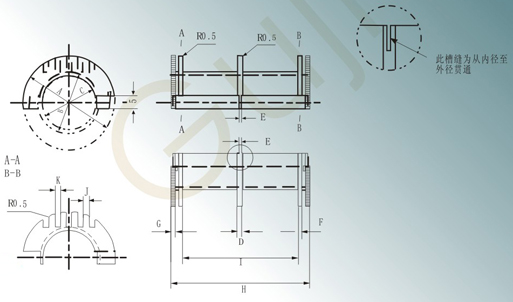

Check the main design dimensions as shown: XR-10

Icon code

|

Design size

|

Tolerance

|

A

|

30.00

|

Minimum value

|

|

B

|

19.00

|

The maximum value

|

|

C

|

17.00

|

Minimum value

|

|

D

|

1.50

|

Reference

|

|

E

|

0.50

|

Reference

|

|

F

|

1.00

|

±0.10

|

|

G

|

1.50

|

The maximum value

|

|

H

|

39.0

|

±0.30

|

|

I

|

31.0

|

±0.10

|

|

J

|

2.00

|

±0.10

|

|

K

|

1.50

|

Reference

|

● Detection tool:digital caliper or micrometer.

● Indicate the code for inspection.

● The number of outlet slots is 4×2.

● hole A is not roundness≤0.20mm,both sides of the hobbing plane of the parallelism≤0.20mm,no significant warping.

● hole hole anastomosis is not allowed to have a step,feel smooth and unimpeded.

● no residual shape or damage,color is no different normal

● finish up to▽7 or more,but allow for harmless scars and miniatures.

● Metal-free impurities or other debris,containing metal,debris products,must be waste separation.

● no melting marks,no internal pores bright spot.There are stomatal highlights(excluding melting marks)products for foreign goods.

● no flash,burr and excess material.Key parts of the burr≤0.05 mm.

● anti-pressure≥25 kg/square centimeter,no damage.

● feel a strong elasticity,and not brittle.

● hardness,wear resistance are suitable for high-speed heavy-duty rotation.

● Selection of raw materials must meet the requirements of the EU ROHS directive,and has UL yellow card certification and fixed-point supply.

● heat distortion temperature≥120 degrees Celsius,insulation resistance must be≥1000M ohm,flame retardant UL94Vo level/0.8-3.2mm.

● other structures should meet the transformer manufacturing process as the standard.